Getting the Simulation Right with Proper Material Data: The Material Digital Twin Approach

Basic Information

Accurate injection molding simulation results heavily rely on material properties data. In this webinar, our expert will delve into the fundamentals of material properties and parameters, exploring the latest techniques in material testing, as well as the comprehensive range of testing equipment, services, and resources provided by the Moldex3D Material Research Center.

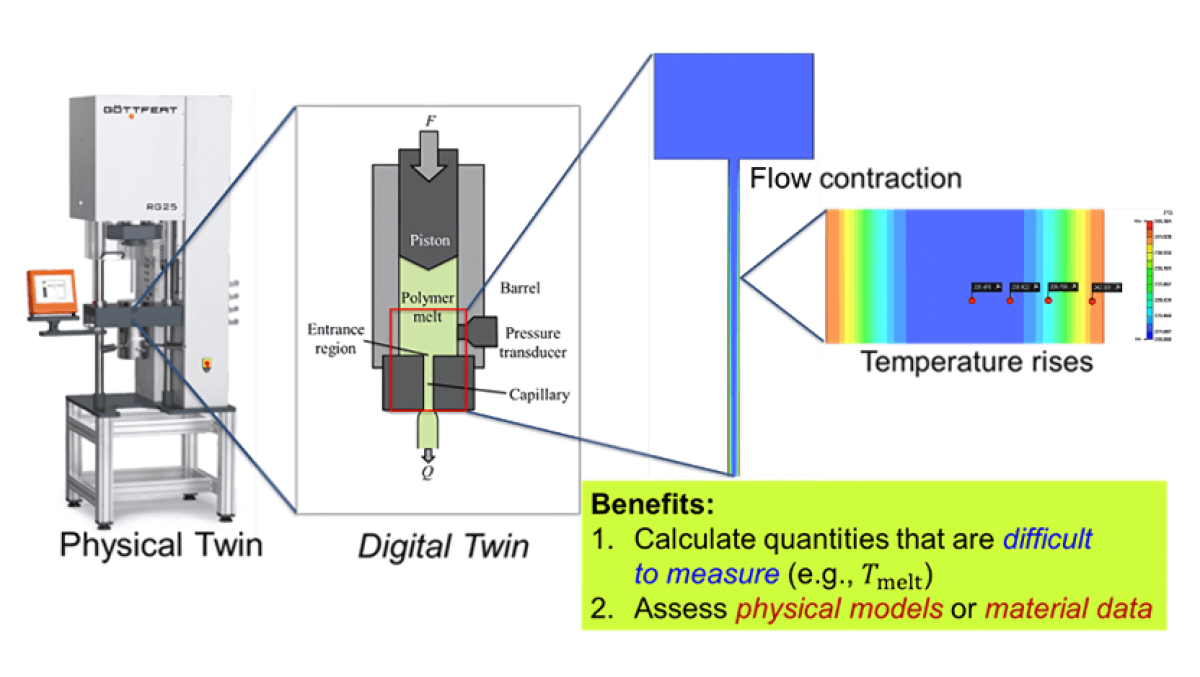

In addition, a pioneering material digital twin can be directly applied in the measurement process. For instance, shear viscosity is the most critical property during the injection molding filling process. The capillary rheometer, widely used for measuring the shear viscosity of polymeric fluids, serves as an example. For example, when measuring viscosity, we set the measurement temperature, assuming the entire system is in a steady-state thermal condition. However, aside from imperfections in the instrument’s heating design causing uneven cavity temperatures, shear heating during flow can raise the temperature near the shear layer at the tube wall above the set temperature. The correction of the temperature (shear heating correction) rises using the material digital twin approach is one of the key techniques that will be introduced in this webinar.

What You Will Learn

- Overview of Moldex3D Material Testing Center

- Insights into material properties and material parameters

- Updates in material characterization techniques and laboratory equipment

- The material digital twin approach to enhance data quality

Speakers

Joe Wang Ph.D., Manager, Material Center

CoreTech System Co., Ltd. (Moldex3D)

〒N/A

8F-2, No.32, Taiyuan St., Zhubei City, Hsinchu County 302, Taiwan

Company Profile

About CoreTech System (Moldex3D)

CoreTech System Co., Ltd. (Moldex3D) has been providing the professional CAE analysis solution “Moldex” series for the plastic injection molding industry since 1995, and the current product “Moldex3D” is marketed worldwide. Committed to providing advanced technologies and solutions to meet industrial demands, CoreTech System has extended its sales and service network to provide local, immediate, and professional service. CoreTech System presents innovative technology, which helps customers troubleshoot from product design to development, optimize design patterns, shorten time-to-market, and maximize product return on investment (ROI). More information can be found at Moldex3D Website.